Carbon Fiber Mirror Covers

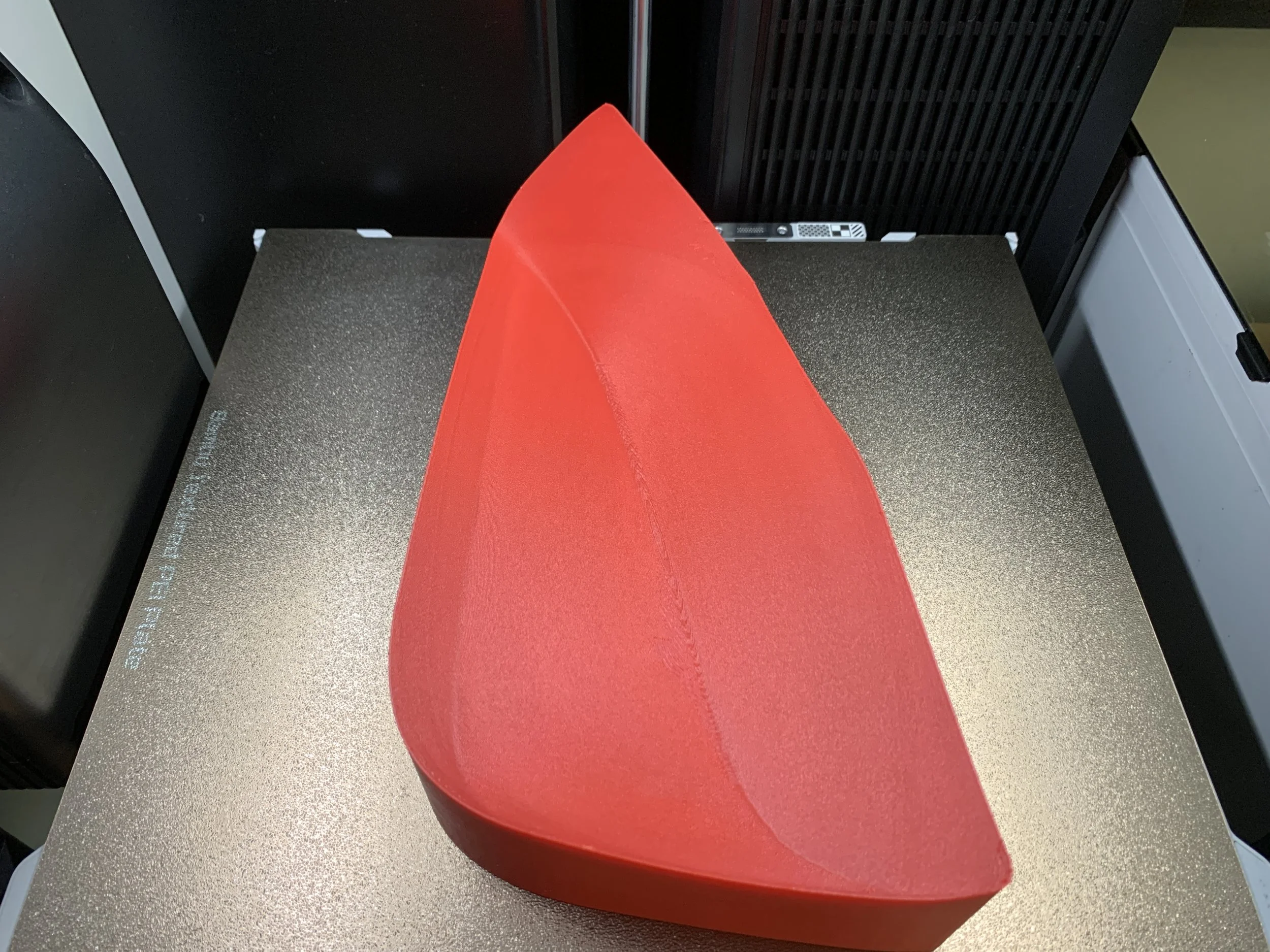

From concept to reality, this project was made possible using all the tools I have at my disposal. To start, I used a metrology grade 3D scanner to reverse engineer a mirror cover from a 3rd gen Toyota Tacoma. The mesh file from the scan was then modelled in SolidWorks to create a mold off the surface, which was then printed on the Bambu Lab H2D - A large format and high temperature capable 3D printer. After some light postprocessing of the mold,